What Is Permanent Radial Swaging? An Introduction for Aircraft Hydraulic Systems

In the world of modern aviation, the safety and performance of an aircraft rely heavily on the quality of its hydraulic and fuel systems. One critical process that ensures leak-proof, high-pressure connections in these systems is permanent radial swaging.

What Is Radial Swaging?

Radial swaging is a precision metal forming process where a hydraulic tool compresses a metallic sleeve or ferrule around a tube or fitting. The goal is to create a permanent, high-strength connection without welding, soldering, or threaded joints. The swaging process is widely used in aerospace applications for hydraulic, pneumatic, and fuel lines due to its proven reliability under extreme conditions.

Unlike conventional connections, radial swaging applies even compressive forces around the entire circumference of the fitting, resulting in a uniform, secure joint with minimal risk of leakage or fatigue failure.

Why Is Radial Swaging Used in Aviation?

Radial swaging plays a crucial role in aircraft maintenance and assembly because of its unique benefits:

-

Leak-free sealing for high-pressure fluid lines

-

Lightweight assemblies without welding

-

Long-term vibration resistance

-

Consistent, repeatable results across multiple assemblies

-

Reduced maintenance and inspection requirements

In aviation, safety is non-negotiable. Hydraulic systems control critical functions like landing gear, flight controls, and braking. Any failure in a hydraulic line could have serious consequences. Radial swaging provides manufacturers and MROs (Maintenance, Repair, and Overhaul providers) with a highly dependable connection method approved by leading OEMs and regulatory bodies.

How Does the Permanent Swaging Process Work?

The permanent swaging process uses specialized hydraulic or pneumatic swaging tools that apply radial compression on a metal sleeve. The sleeve deforms around the inserted tube and fitting, creating a permanent interference fit that seals the joint both mechanically and hydraulically.

Industry-leading systems like Permaswage and DLT swaging tools are commonly used for this process. These systems are engineered to deliver consistent compression forces and produce joints that meet strict aerospace standards such as AS9100, EN9120, and OEM specifications.

Where Is Radial Swaging Applied?

Permanent radial swaging is extensively used in:

-

Hydraulic lines

-

Fuel lines

-

Pneumatic systems

-

Oxygen and inert gas lines

-

Military and commercial aircraft assembly

-

Business jets and regional aircraft

The Importance of Using Certified Swaging Tools

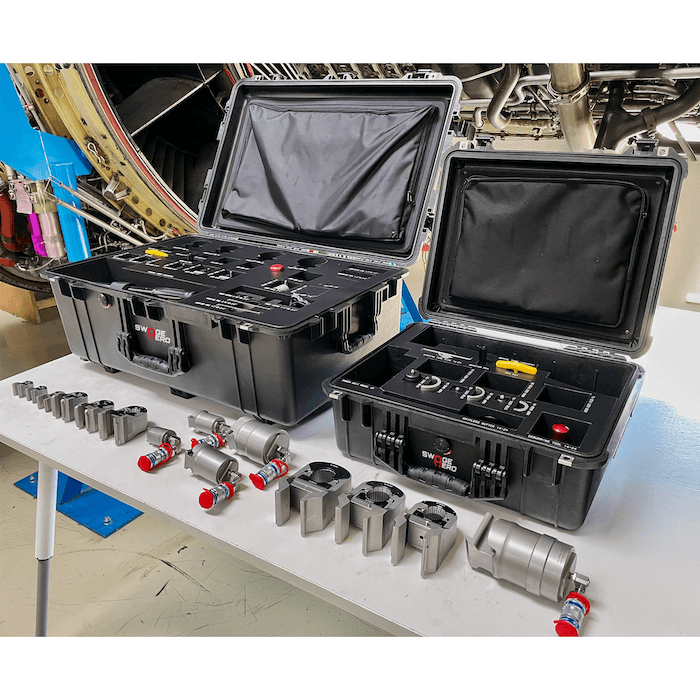

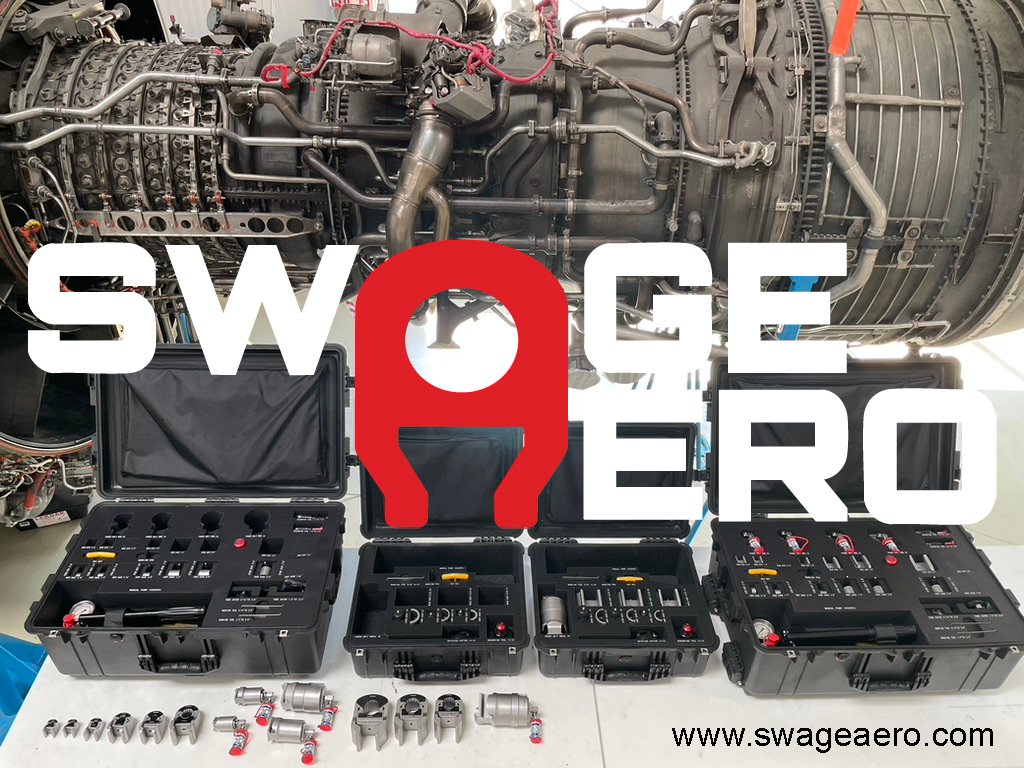

Using high-quality, properly certified swaging tools is essential to ensure safety and compliance in the aerospace industry. Poorly swaged connections can result in system leaks, component failures, and costly downtime. That’s why leading aviation OEMs and MRO facilities rely on certified tooling solutions such as the systems provided by SwageAero.

SwageAero: Your Partner for Aviation Swaging Solutions

SwageAero supplies a full range of Permaswage-compatible swaging tools, hydraulic assembly equipment, and permanent swaging toolkits trusted by aerospace professionals worldwide. Our product line includes:

-

Permanent Radial Swage Toolkits

-

Internal Swaging Toolkits

-

Aircraft Cable Swaging Equipment

-

DLT Portable Swaging Tools

-

Certified hydraulic assembly tools for aviation applications

For more information on how SwageAero can support your maintenance or production operations, please contact us.

Comments (0)

Be the first one to comment!

Search

Categories

More Posts

Aug 18 2025 | 0 Comments

Aug 14 2025 | 0 Comments

Aug 12 2025 | 0 Comments

Jun 16 2025 | 0 Comments

Jun 16 2025 | 0 Comments