The Role of Swaging Tools in Aircraft Hydraulic Line Assembly

In modern aircraft, hydraulic systems are the lifeblood that powers many essential flight functions, including landing gear, brakes, flight controls, and thrust reversers. To ensure these systems function safely under high pressure and extreme conditions, the assembly of hydraulic lines requires absolute precision. Swaging tools play a critical role in achieving the secure, leak-free connections demanded by the aviation industry.

Why Precision Matters in Aircraft Hydraulic Lines

Aircraft hydraulic systems typically operate at pressures ranging from 3,000 to 5,000 PSI, with some military applications reaching even higher. At these pressures, even a minor leak or improperly fitted hydraulic connection can lead to catastrophic failures, grounding aircraft and compromising safety.

Precision is not optional — it’s mandatory. This is why certified swaging tools, such as those provided by SwageAero, are essential for hydraulic line assembly, whether in aircraft manufacturing or maintenance operations.

How Swaging Tools Work in Hydraulic Assembly

Swaging tools apply controlled radial compression to form permanent, high-strength metal-to-metal seals around hydraulic tubes and fittings. The process eliminates the need for threads, welding, or flaring. Instead, the tube is inserted into a specially designed fitting (such as a Permaswage fitting), and the swaging tool compresses the sleeve to create a secure, leak-tight connection.

The controlled force applied by the swaging head ensures:

-

Uniform deformation of the sleeve

-

Consistent sealing pressure across the entire joint

-

Repeatable, certified-quality connections every time

Key Advantages of Using Swaging Tools for Aircraft Hydraulics

Using specialized swaging tools for hydraulic line assembly offers several critical advantages:

-

Leak-proof connections: Prevent fluid leaks even under extreme pressure.

-

Weight reduction: No need for heavy flared or welded joints.

-

Corrosion resistance: High-quality fittings minimize corrosion over time.

-

Reduced maintenance: Long-lasting joints reduce inspection intervals.

-

Faster assembly times: Swaging is quick, repeatable, and operator-friendly.

-

OEM and regulatory compliance: Swaging methods meet aviation authority standards worldwide.

Where Are Swaging Tools Used in Aircraft Hydraulic Systems?

Swaging tools are widely used across both commercial and military aircraft, in both OEM manufacturing and ongoing MRO (Maintenance, Repair & Overhaul) operations. Applications include:

-

Hydraulic actuator lines

-

Flight control systems

-

Landing gear hydraulic lines

-

Brake systems

-

Cargo door actuators

-

Thrust reverser mechanisms

The Importance of Certified Swaging Tools

In aerospace, tooling quality directly impacts flight safety. All swaging tools used in aircraft hydraulic systems must meet strict certification standards and be compatible with approved fittings. Using non-certified or worn-out tools can lead to improper swaging, increasing the risk of leaks or failure.

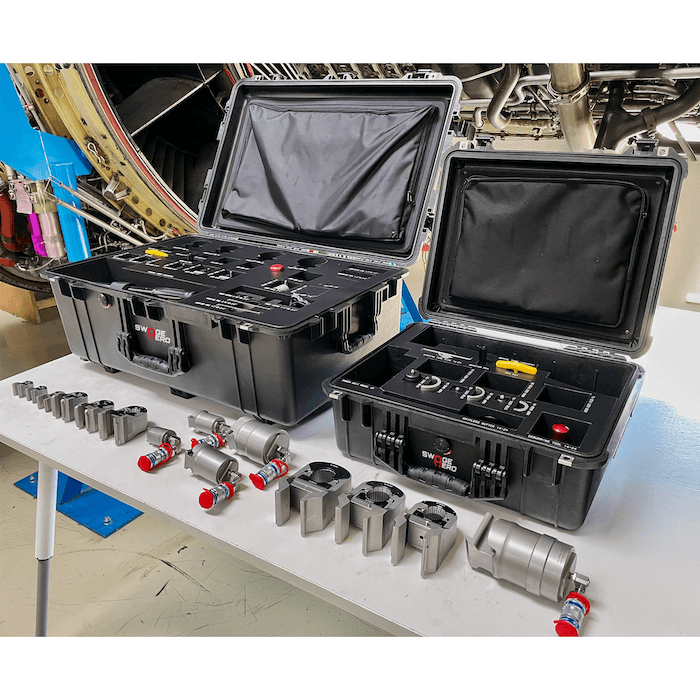

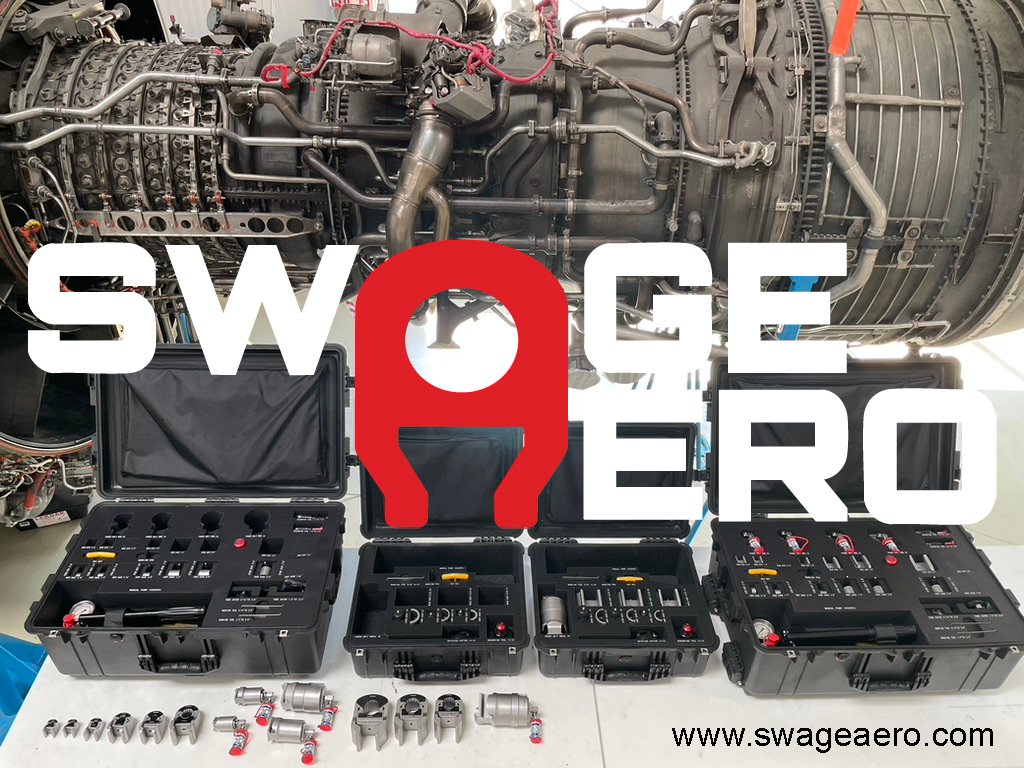

SwageAero supplies only certified swaging tools designed to meet aviation standards and OEM specifications, including Permaswage-compatible solutions widely trusted in the industry.

SwageAero: Your Trusted Supplier for Aircraft Hydraulic Swaging Tools

At SwageAero, we offer a full range of certified hydraulic assembly equipment, including:

-

Permanent Radial Swaging Toolkits

-

Internal Swaging Tools

-

DLT Portable Swaging Systems

-

Aircraft Cable Swaging Equipment

-

Permaswage-Compatible Fittings & Tooling

Our mission is to support aerospace OEMs, MROs, and technicians worldwide by providing the precision tools they need to maintain safety and performance in every hydraulic system.

For more information about our full product range, please contact us.

Comments (0)

Be the first one to comment!

Search

Categories

More Posts

Aug 18 2025 | 0 Comments

Aug 14 2025 | 0 Comments

Aug 12 2025 | 0 Comments

Jun 16 2025 | 0 Comments

Jun 16 2025 | 0 Comments