How to Select the Right Swaging Toolkit for Aircraft Maintenance

Selecting the right swaging toolkit is a critical decision for any aircraft maintenance organization, whether you're a global MRO, OEM manufacturer, or small maintenance facility. The correct tools not only ensure high-quality repairs and assemblies but also help maintain full compliance with aviation regulations and OEM specifications.

Why Swaging Toolkit Selection Matters

Swaging tools are essential for assembling hydraulic, fuel, pneumatic, and cable systems in aircraft. If the wrong tool is used, the consequences can range from minor leaks to major system failures. That’s why selecting certified, precise, and purpose-built swaging equipment is essential for any aviation operation.

Proper swaging creates:

-

Reliable, leak-free hydraulic connections

-

Long-term durability under vibration and pressure

-

Compliance with OEM and aviation authority standards

-

Reduced risk of rework or system failure

Factors to Consider When Selecting a Swaging Toolkit

When purchasing swaging equipment for aircraft maintenance, here are key factors to evaluate:

1. Type of Swaging Required

-

Permanent Radial Swaging: Used for hydraulic and fuel line fittings using radial compression sleeves.

-

Internal Swaging: Used for internally expanding sleeves in specific applications.

-

Cable Swaging: Used for aircraft control cables and support cables.

Each type requires a different toolkit and head configuration.

2. Tool Compatibility (Permaswage and OEM Standards)

Ensure the swaging toolkit is fully compatible with the fittings and systems specified by the aircraft OEM (such as Boeing, Airbus, Bombardier, Gulfstream, etc.).

Many aircraft rely on Permaswage-compatible fittings. Using fully certified tooling ensures consistency and regulatory compliance.

3. Portable vs. Bench Systems

-

Portable DLT Swaging Tools: Lightweight and field-serviceable for onsite repairs.

-

Bench-Top Hydraulic Systems: Suitable for larger repair shops or manufacturing facilities.

4. Certification & Traceability

Always select swaging tools that come with full certification and traceability records. This helps during inspections, audits, and ensures long-term regulatory compliance.

5. Maintenance and Calibration Support

Swaging tools must be properly maintained and recalibrated at regular intervals to ensure accuracy. Choose suppliers that offer maintenance services, spare parts, and recalibration.

6. Supplier Expertise

Work with suppliers who specialize in aviation-grade tooling and understand the quality standards required for aerospace applications.

Common Mistakes to Avoid

-

Using general-purpose industrial swaging tools instead of certified aviation equipment.

-

Purchasing from non-specialized suppliers who do not provide full traceability.

-

Failing to maintain and calibrate swaging tools regularly.

-

Using tools not approved by the aircraft manufacturer.

SwageAero: Supplying Certified Swaging Toolkits for Aviation

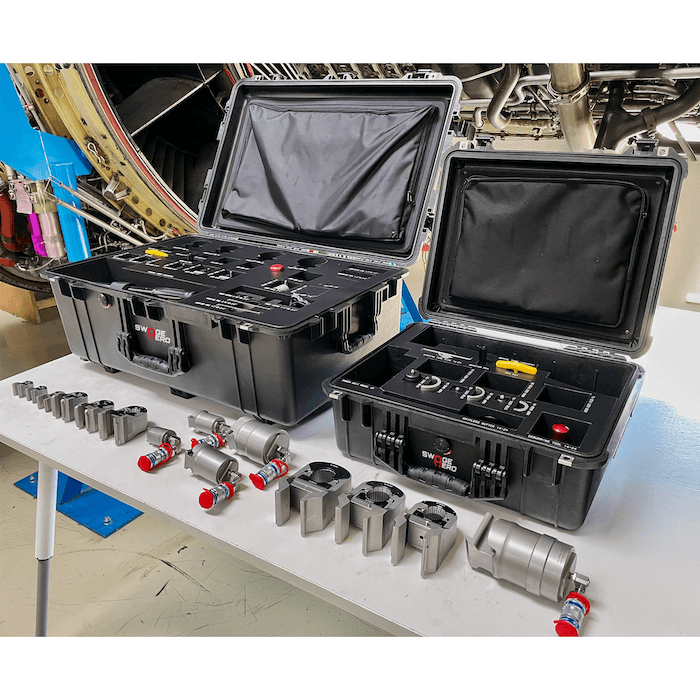

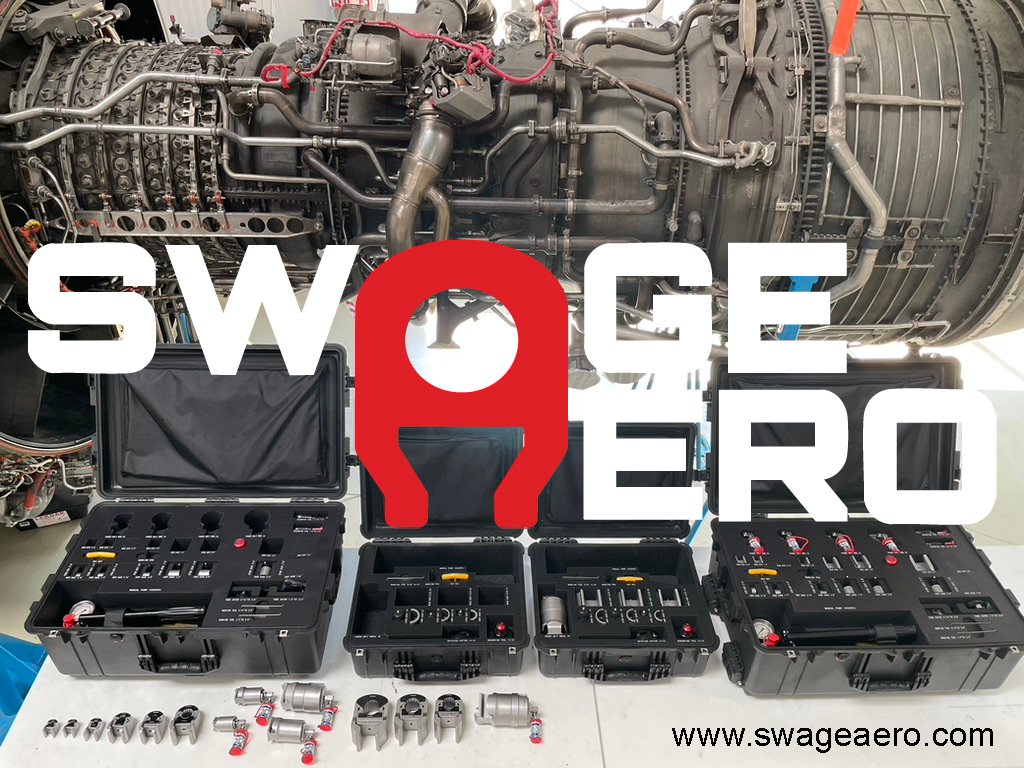

At SwageAero, we specialize in providing certified, aviation-grade swaging toolkits for hydraulic, fuel, pneumatic, and cable assembly. Our product line includes:

-

Permanent Radial Swaging Toolkits

-

Internal Swaging Toolkits

-

Cable Swaging Equipment

-

Portable DLT Swaging Tools

-

Certified Calibration and Maintenance Support

Our tools are fully compatible with Permaswage fittings and meet the strict standards required by aircraft OEMs and regulatory agencies.

Conclusion

Choosing the right swaging toolkit is an investment in safety, reliability, and regulatory compliance. By partnering with experienced aviation tooling suppliers like SwageAero, maintenance organizations can ensure they have the correct tools, documentation, and support to keep aircraft safe and operational.

For more information or to request a quotation, please contact us.

Comments (0)

Be the first one to comment!

Search

Categories

More Posts

Aug 18 2025 | 0 Comments

Aug 14 2025 | 0 Comments

Aug 12 2025 | 0 Comments

Jun 16 2025 | 0 Comments

Jun 16 2025 | 0 Comments